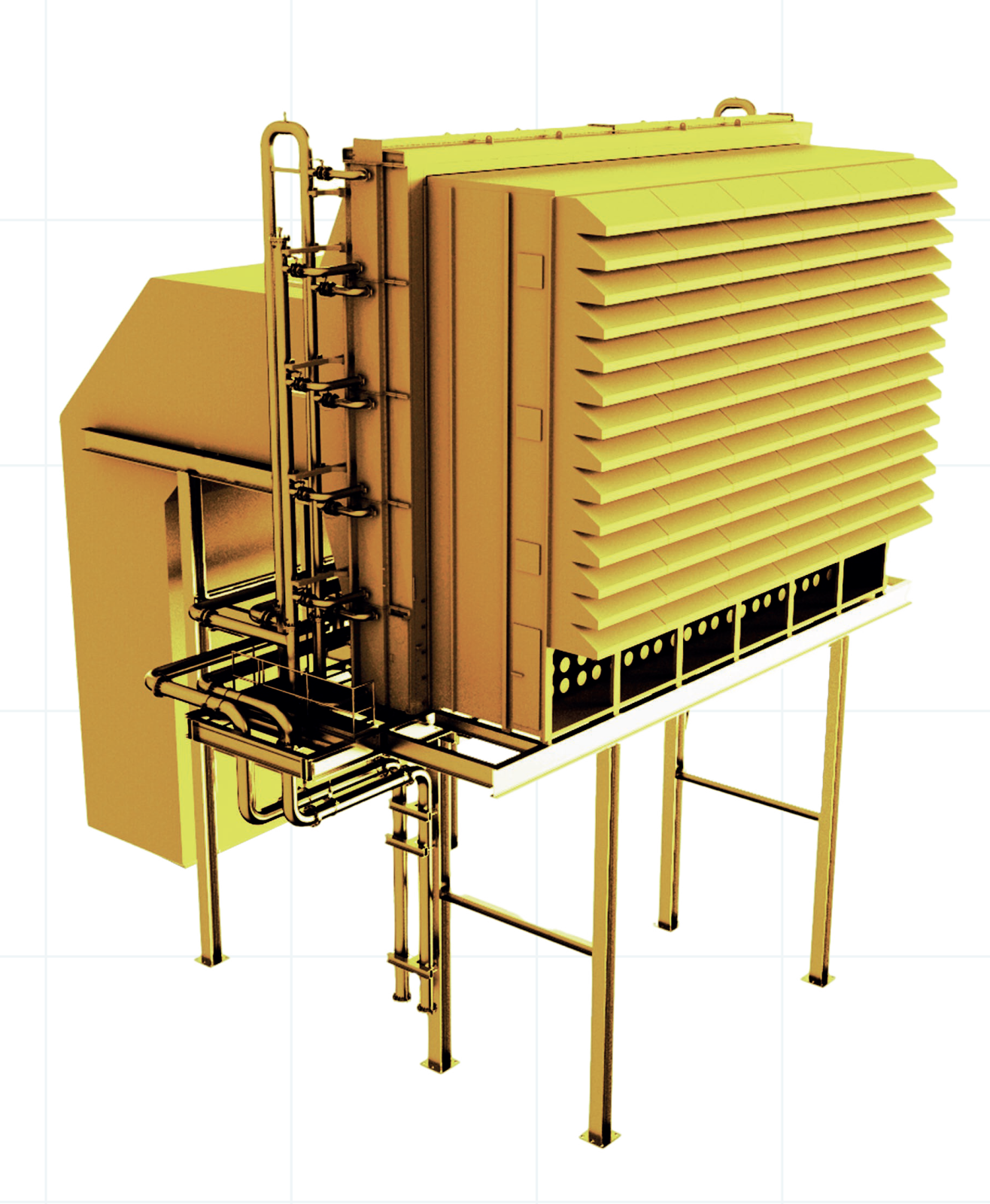

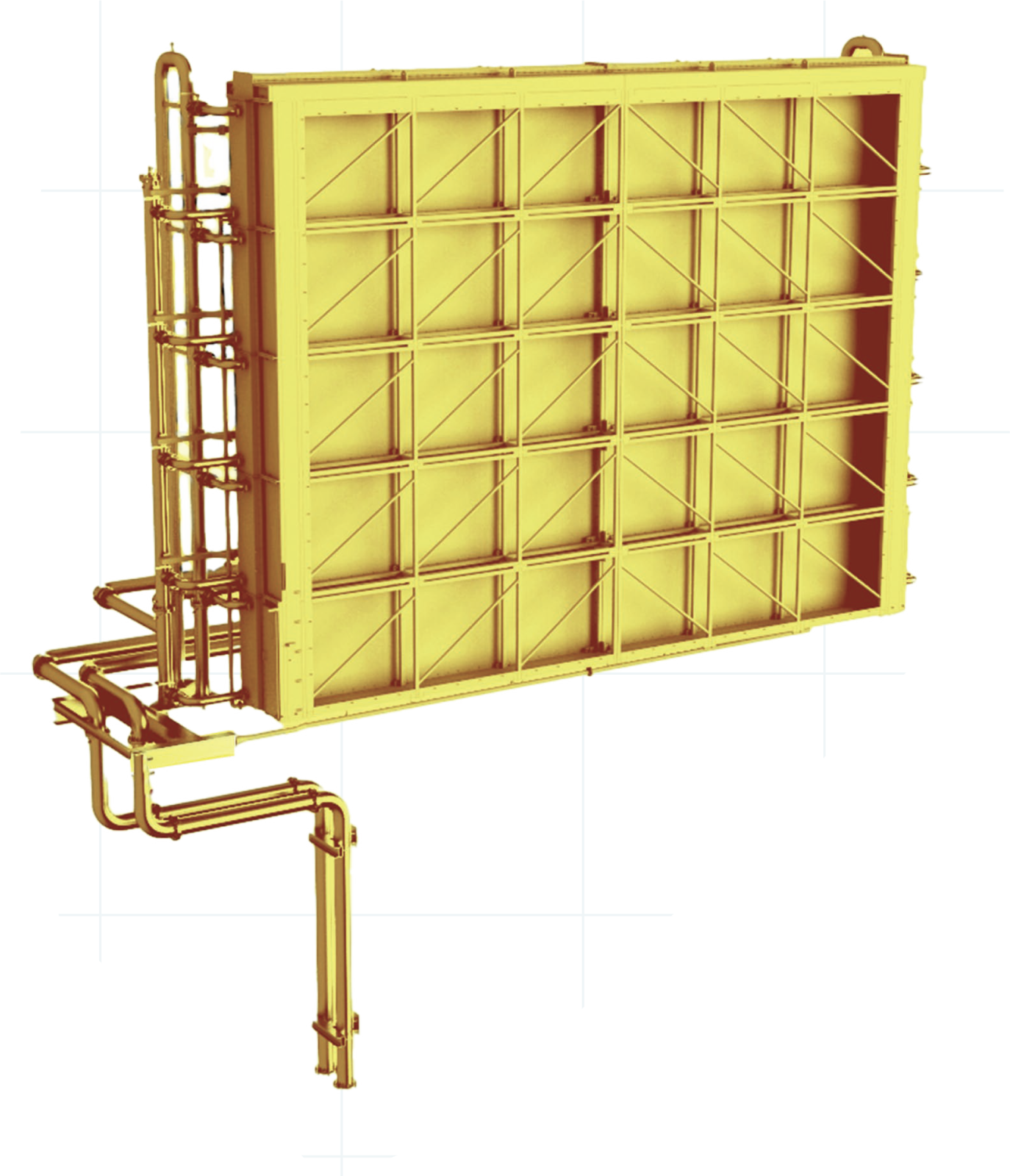

Modernisation and Streamlining of Gas Power Plants

Why We Committed to the Project

Modernising conventional power plants and integrating advanced energy storage solutions are key steps on the path towards a more stable and sustainable energy mix. Arizona Public Service Company (APS) is the largest and longest-operating electricity provider in the state, supplying power to over 1.3 million customers.

To enhance grid stability and support the integration of renewable energy sources, APS is upgrading its power plants with a unique energy storage solution that combines the flexibility of conventional generation with the advantages of battery storage.