Turnkey Small-Scale Plants

We support global technologists by helping them turn their unique technologies into real projects. Our expertise lies in developing modular small-scale gasification plants that generate high value outputs from non-recyclable waste or biomass. This approach enables us to deliver innovative solutions that meet the specific needs of our clients.

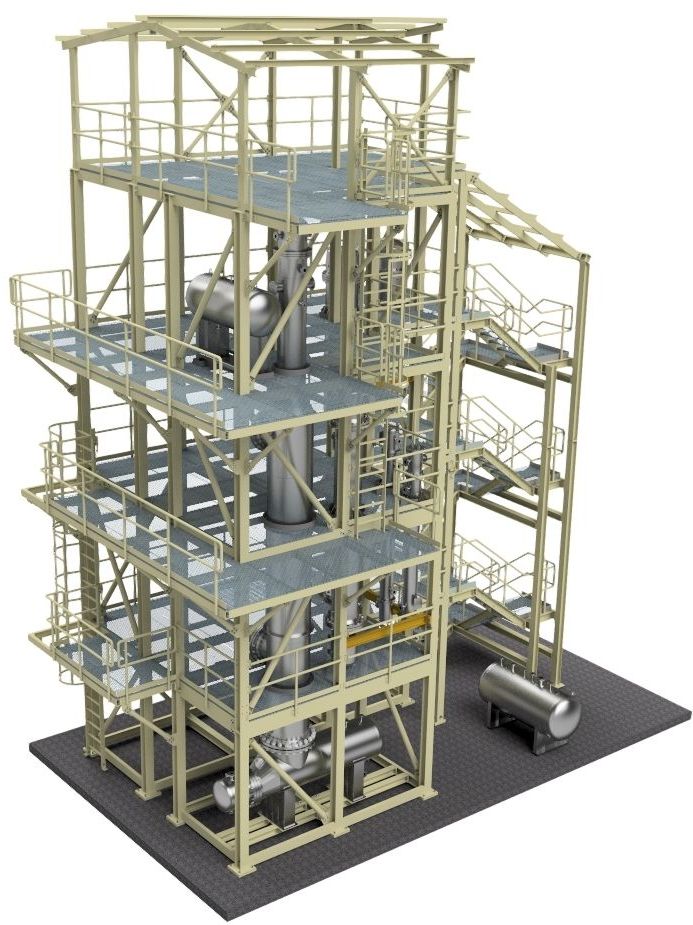

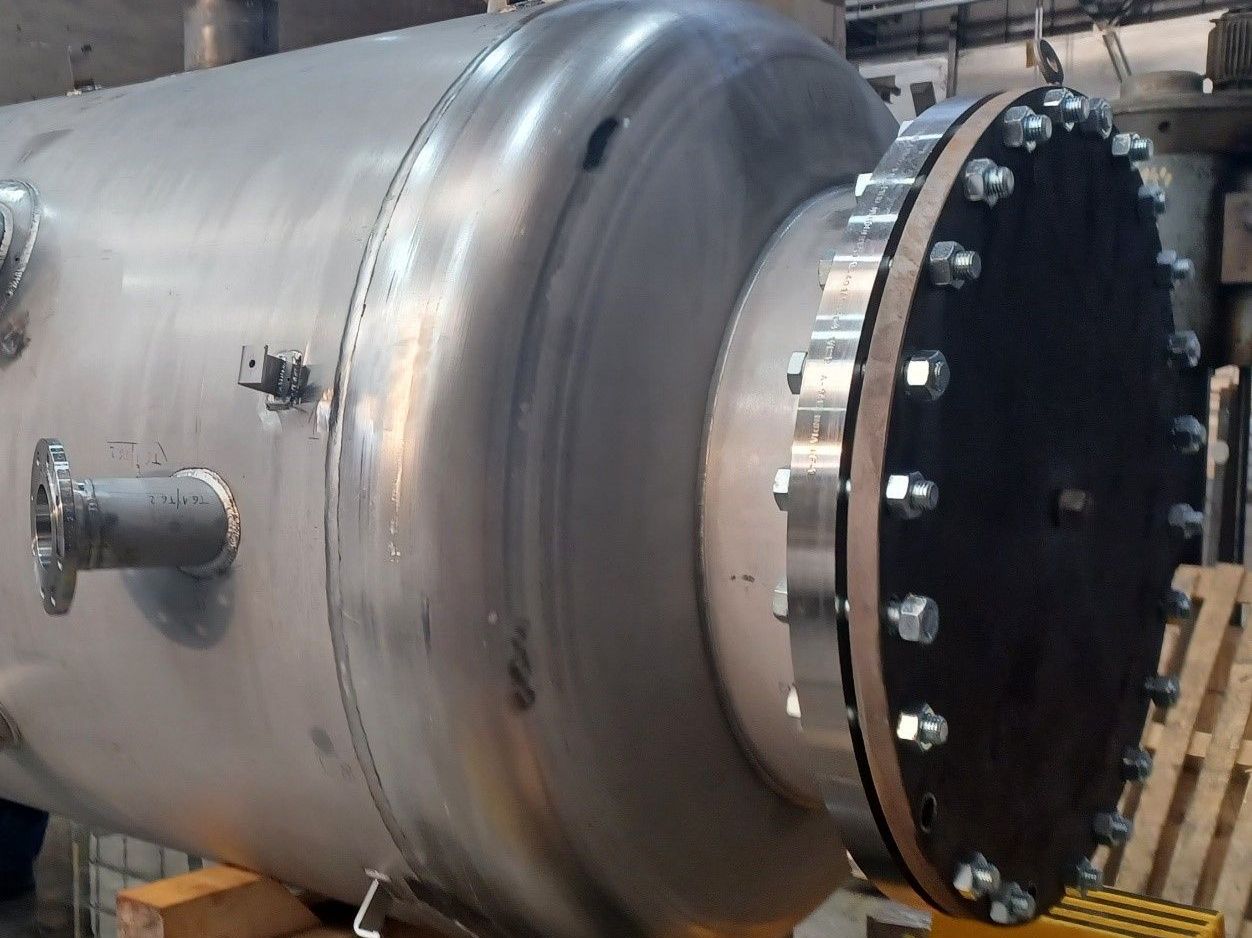

Our services encompass the entire scope of Engineering, Fabrication, and Installation of PED pressure equipment (gas separators, heat exchangers, reactors, coolers) and integrated process piping. On top, we provide modularized building solutions consisting of prefabricated, shippable steelwork modules that integrate all mechanical and electrical equipment.