2JCP is a globally recognized leader in providing engineered solutions to a wide range of industries. With over thirty years of experience, we have established a strong global presence, serving prestigious industrial and energy customers on every continent, including Europe, North America and Australia.

Our headquarters and manufacturing plants in the Czech Republic are complemented by strategically located sales and engineering centers in the UK and USA, ensuring we are always close to our customers and ready to provide 24-hour support.

We employ highly qualified staff across all necessary fields in all our offices and production plants.

We have set up our sales, engineering and manufacturing locations close to our customers.

Our business grows with our customers leading to nearly 100 M EUR revenue in the near term.

Our journey began decades ago with solutions for gas-fired energy sources, but today, we stand at the forefront of innovation in sustainable energy technologies. By leveraging our extensive industry experience and cutting-edge engineering service, we develop comprehensive solutions that bridge the gap between conventional and renewable energy systems. This unique position allows us to guide our clients through the complexities of the energy transition, ensuring a smooth and efficient shift towards more sustainable practices.

We have grown through a combination of engineering know-how, courage, common sense and the proven skills of our workers. We are the bridge between thinking and making, between an idea and a multi-ton product, between our generation and the next.

Many of our works delivered around the world were the first of their kind, whether they were components of drilling systems or green methanol production solutions. We have always tended to be co-creators of engineering solutions, never giving up on any technological challenge. Whatever can be invented can be manufactured.

Our roots are in the welding shop where it all began thirty years ago. We know well enough about steel to make it work perfectly for the energy projects of the future.

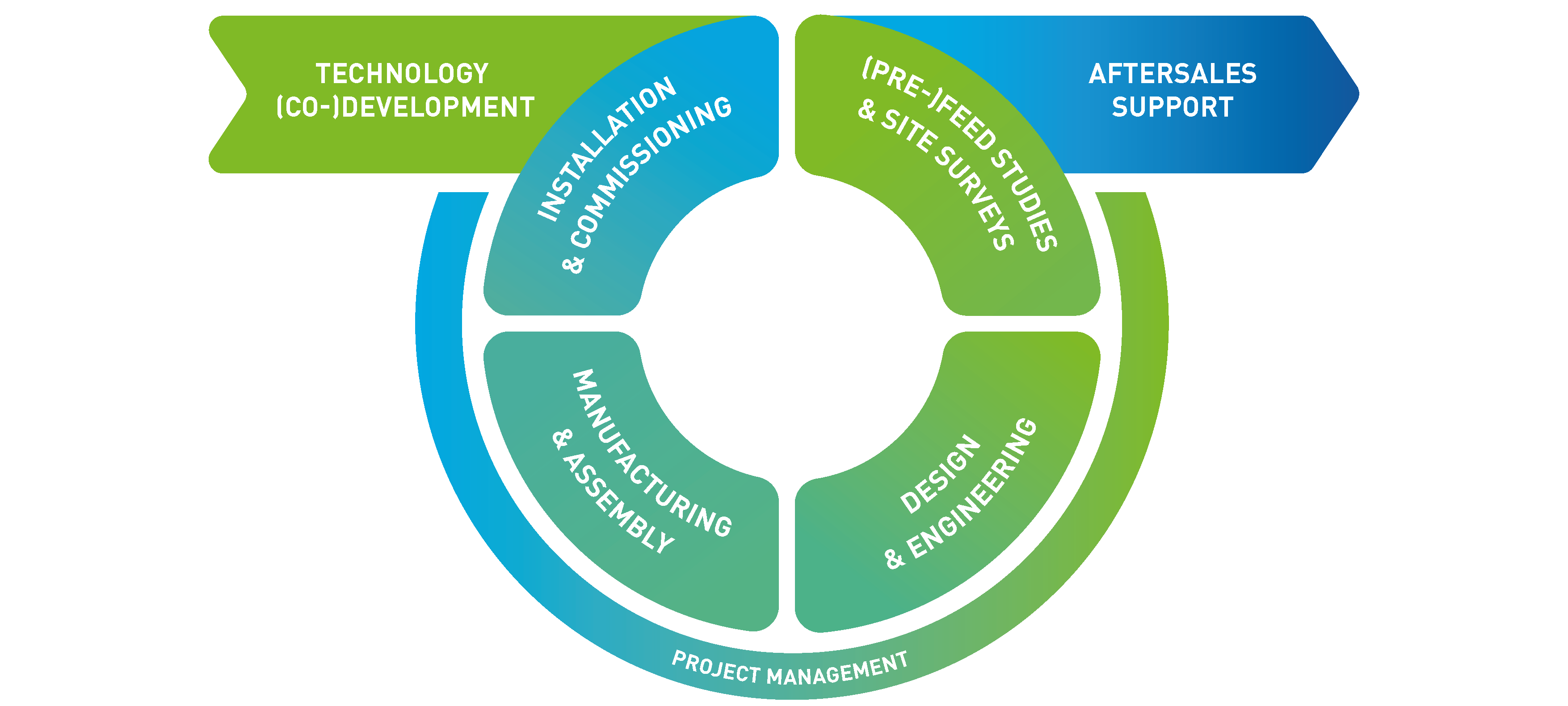

We also know that even a well-made component is useless until it's delivered, up and running. That's why we handle the entire product lifecycle - from design to go-live.

We offer a comprehensive portfolio of engineered solutions, primarily focused on balance of plant for gas turbines and modular solutions across various renewable energy sectors. Our expertise spans a wide range of critical components and systems, each designed and manufactured to the highest standards.

This diverse array of products allows us to provide holistic, integrated solutions that optimize performance and efficiency in both traditional and renewable energy applications, underlining our commitment to driving innovation in the energy sector.

We take pride in our long-standing partnerships with the most prestigious industrial and energy companies around the globe. Over the course of three decades, we have established ourselves as a trusted provider, supplying and installing a vast array of power and clean energy equipment across diverse markets and geographical regions.

Our footprint extends to numerous locations worldwide, from the sun-drenched coasts of Australia to the bustling energy hubs of the United States, the rugged landscapes of Scotland, the fjords of Norway, and the innovative energy sectors of Denmark.

19.9.2025

We are exhibiting on the Hydrogen Technology & Carbon Capture World Expo. Visit us in Hamburg!