2JCP to Create a Groundbreaking Carbon Capture and Hydrogen Purification Plant for KEW Technology

Ripley, Derbyshire, January 30, 2024 – 2JCP has been awarded an engineering and manufacturing contract by KEW Technology to design and build a unique modular CCH₂ (Carbon Capture and Hydrogen Purification) plant at KEW's Sustainability Energy Center in Birmingham, UK.

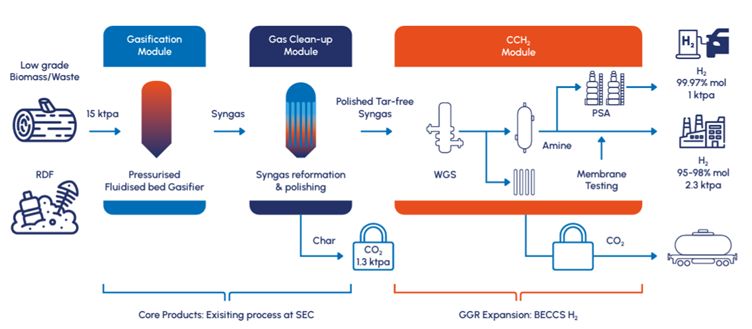

KEW Technology, a recipient of Phase I funding from the UK government's Greenhouse Gas Removal (GGR) competition, has pioneered a modular Bioenergy with Carbon Capture and Storage (BECCS)-H₂ GGR solution known as the Carbon Capture and Hydrogen Purification (CCH₂) product. This innovative technology is designed to facilitate cross-sector deep decarbonization and generate negative emissions, producing high-purity CO₂, industry-grade hydrogen (H₂), and fuel cell vehicle (FCV) hydrogen using KEW's advanced gasification process.

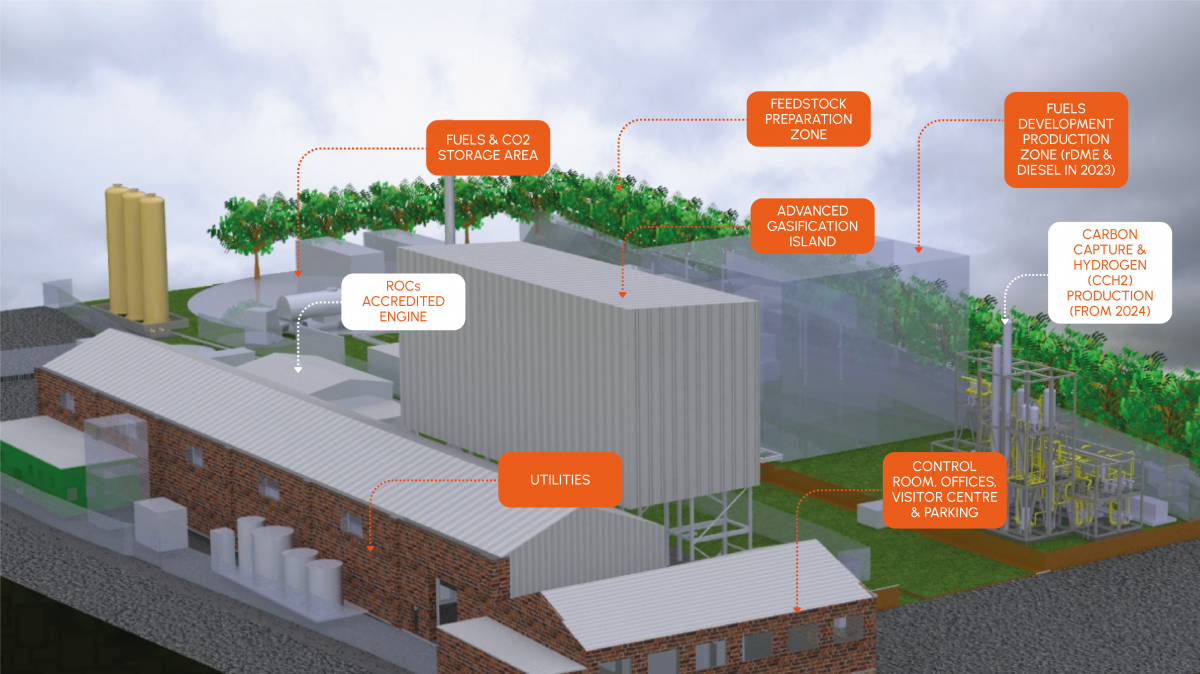

KEW Technology has selected 2JCP to design and build their world's first CCH₂ plant, strategically situated at KEW's Sustainable Energy Center in Birmingham, UK. This plant will be connected to the existing Advanced Gasification Plant, using outputs from the current production of high-quality synthetic gas.

Planned integration of the CCH₂ plant within KEW’s Sustainable Energy Center