Where are we active?

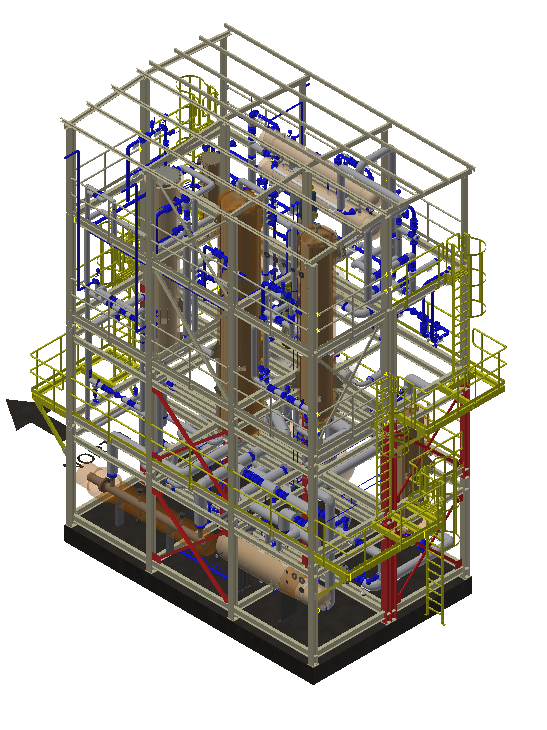

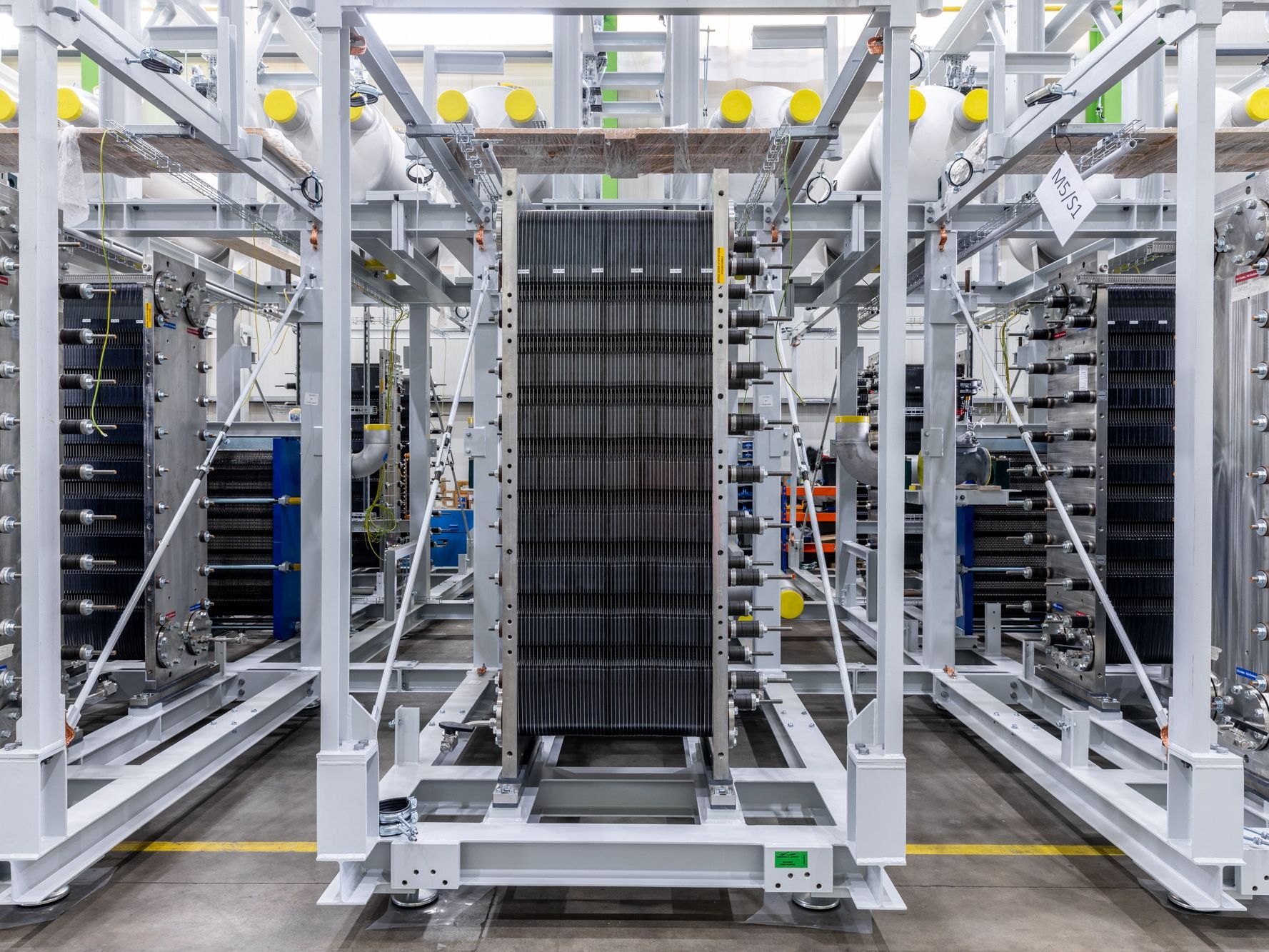

As a leading engineering and manufacturing company, we are proud to actively participate at numerous hydrogen projects and technologies, including industrial-scale electrolysers or hydrogen co-powered power plants.

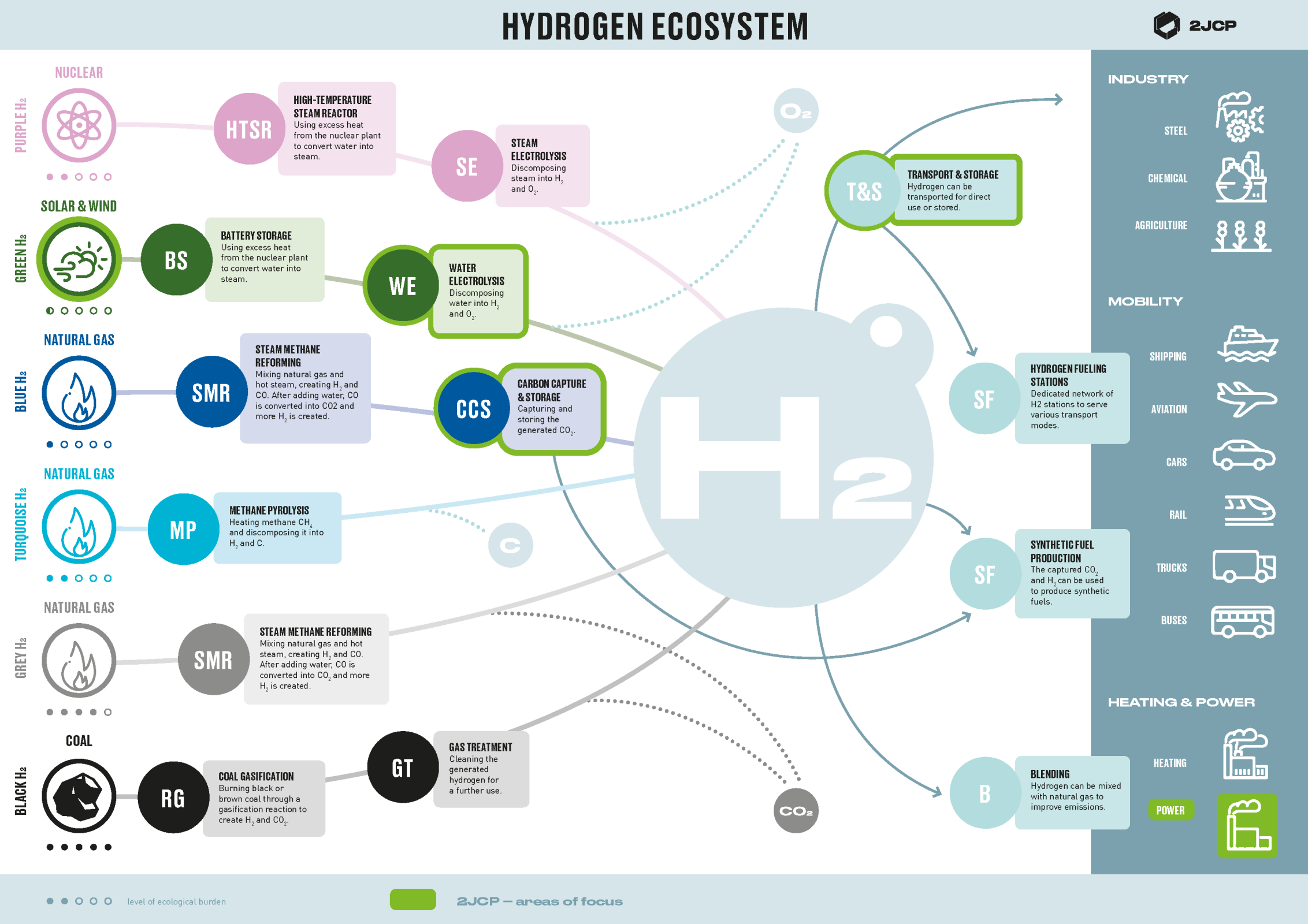

Check our view on the entire hydrogen ecosystem, key sources and main use cases of hydrogen and which areas of business we actively support.